Eight-station pet food bag packaging machine

The pet food we see on the market generally includes cat snacks, dog snacks, rabbit food, etc. These pet foods are generally packaged in stand-up bags (premade bags). The stand-up bags for packaging pet food generally have four sides. Seal ordinary bags, zipper stand-up bags, and eight-side seal zipper bags.

So if we use an automatic packaging machine for fully automatic packaging, we can choose a single-station pet food bag packaging machine or an eight-station pet food bag packaging machine for packaging according to the product and required speed.

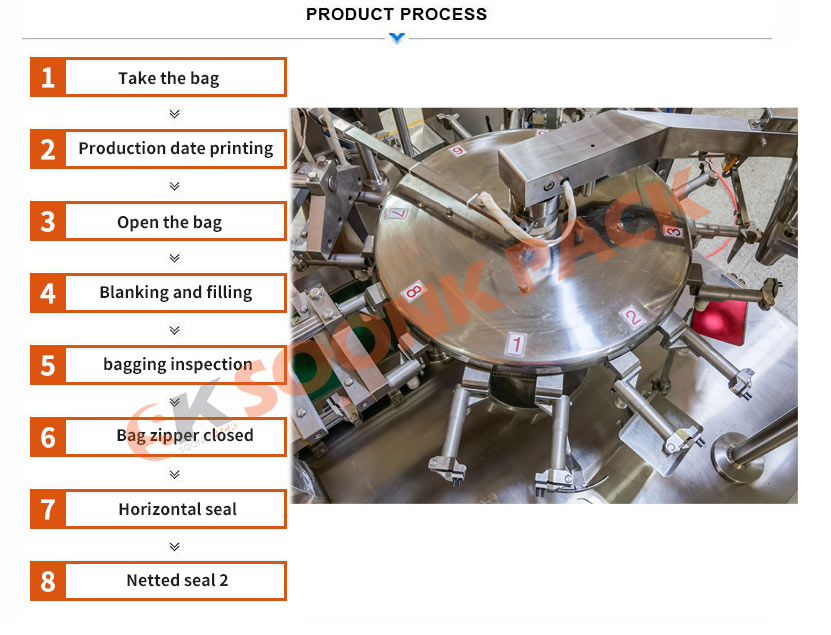

Today we will introduce the fast eight-station pet food bag packaging machine. So what is an eight-station pet food packaging machine? Are you confused? There are 8 stations in the equipment. What functions do they have? Let’s find out next.

soonkpack is a Chinese packaging machine manufacturer with more than 20 years of experience in packaging machine R&D and design. We will provide you with the most suitable packaging solution for your factory based on your actual needs.

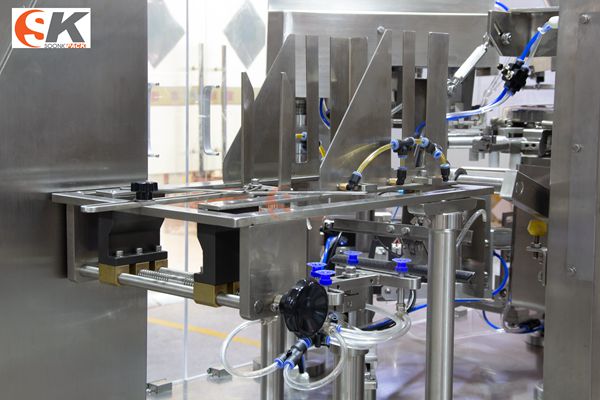

We mentioned above that the eight-station pet food bag packaging machine is suitable for stand-up bags (prefabricated bags), such as four-side seal bags, zipper stand-up bags, eight-side seal zipper bags, etc. When the machine is working, the eight stations are respectively Have its own homework actions. The work process is as follows: take the bag, print the production date, open the bag, unload the material, check the loading, close the zipper bag, seal the bag and output.

After the first station of the eight-station pet food bag packaging machine prefabricated bags (made bags) are placed in the bag placement warehouse, the robot hand picks up the bags, and the manual only needs to place the bags into the bag warehouse. 50-80 bags can be placed at one time (depending on the bag)

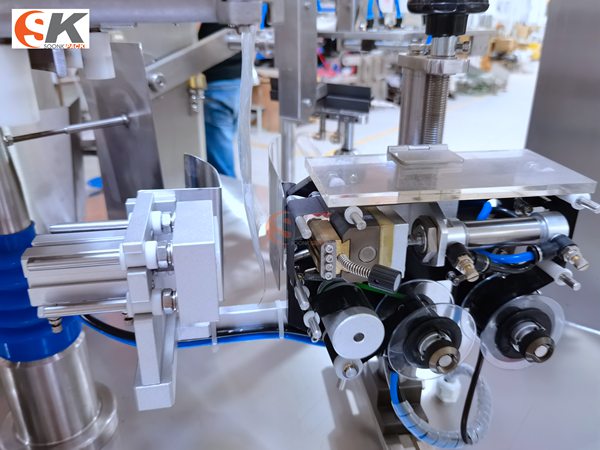

After the robot gives the bag, it moves to the next station and prints the production date. The printing speed is fast and the effect is good. It is very simple to change the date or replace the ribbon.

After the date printing is completed, the eight-station pet food bag packaging machine enters the next station to open the bag. Use a suction cup to open the bag. The success rate of bag opening is 99.9%. If the bag is not opened, the packaging machine will send out a signal. , do not fill and seal, then transfer to another bag.

After the bag is opened, the next station is filled with materials. The main machine of the packaging machine sends a signal to the metering device to inform the bag that the bag is open and can be filled with pet food. Then the combination scale will fill the pet food.

After the material is filled, the next station is the bagging inspection of the material. Check whether the material is filled (whether the bag is empty) and ensure that the packaged bag contains pet food.

After the bagging inspection is completed, our next work station is to close the zipper bag. After closing, we will move on to the next work station.

The next step for the eight-station pet food bag packaging machine is sealing. This is a strip seal. In order to ensure the sealing performance, there is a next seal. After the sealing is completed, it is output.

The eight-station pet food bag packaging machine is completed by each station. Therefore, in addition to packaging pet food, this bag packaging machine can also package various puffed foods. Whole grains, nuts and preserved fruits, banana chips, fruit and vegetable crisps, frozen foods, etc.

You may be interested in:

fully automatic packaging machine line

Automatic Ice Packaging Machine