Guides To Vertical Form Fill Seal Machine

Table of Contents

Convenience is at the core of the contemporary world, and efficient packaging stands out as a crucial element. Whether you’re purchasing a packet of potato chips, a cereal box, or a coffee pouch, it’s likely to be packed by a smart vertical form fill seal (VFFS) machine which was used for the packaging. The introduction of Soonk vertical form fill seal machines has instigated noteworthy transformations in the packaging sector, playing a pivotal role in ensuring the efficient and dependable packaging of a diverse range of products for consumer use.

These machines offer unmatched speed and cost-effectiveness, establishing themselves as indispensable components of packaging operations across different industries. Vertical packaging machines come in many styles. VFFS is one of them, which combines mailbag creation, filling, data printing and accounting functions. A servo motor is used to pull the film, and the deviation is automatically corrected during the film pulling process. The VFFS machine runs smoothly. Both horizontal and vertical seals use reliable moving pneumatic cylinders.

Understanding Vertical Form Fill Seal Machines

In the dynamic world of packaging, efficiency and innovation are key. One such groundbreaking innovation is the vertical form fill seal machine, a technology that has significantly transformed the packaging industry. A vertical packaging machine is a vertically oriented bag forming and filling equipment. It is mainly used in industrial packaging and processing because it provides a more convenient and effective automatic packaging method, saving a lot of time and money.

These machines not only epitomize the advancement in packaging technology but also reflect the changing dynamics of consumer demand and industrial efficiency. This essay aims to provide a comprehensive analysis of VFFS machines, examining their technological intricacies, impact on industries, and the broader implications on global supply chains and environmental sustainability.

The Mechanics of VFFS Machines

Soonk VFFS machines operate on a principle that combines material handling, forming, filling, and sealing into a single, streamlined process. The machine starts by converting a roll of plastic film into a bag, fills the bag with the product, and then seals it – all in a vertical fashion. This process encompasses several innovative features: precision timing, synchronization of multiple mechanical and electronic components, and advanced control systems. The incorporation of technologies such as computer-aided design (CAD), programmable logic controllers (PLCs), and user-friendly human-machine interfaces (HMIs) are pivotal in enhancing the efficiency and flexibility of these machines.

Industry Impact

VFFS machines have significantly impacted multiple industries – food and beverages, pharmaceuticals, cosmetics, and agriculture, to name a few. In the food sector, for instance, they have enabled high-speed packaging of perishable goods under controlled conditions, extending shelf life and maintaining product quality. In pharmaceuticals, the precision and contamination-free environment provided by VFFS machines ensure compliance with stringent regulatory standards.

The adoption of VFFS technology leads to a substantial increase in production rates while reducing labor costs and minimizing material wastage. This economic advantage not only benefits manufacturers but also trickles down to consumers in the form of lower product prices and improved product availability.

Components Of The Vertical Packing Machine

Film Unwind

The film stretching system uses unwinding rollers and tensioners. There is a very long roll of film rolled into a roll, which is called film. Films for vertical packaging machines are usually laminated polyethylene (PE), PET, paper and aluminum foil. The web film will be loaded onto the back of the unwind roller of the VFFS machine. The film pulling system on the roll is driven and pulled by a servo motor. They completely complement each other, pulling smoothly and reliably in one continuous motion. The movement and positioning of the film are precisely controlled by the film drive and tracking system, which typically employs sensors and motors for accuracy. The forming tube, or collar, then shapes this film into a tube, through which the product is funneled into the forming bag.

Printer

Once the film is placed on the printer (optional), a photocell will capture the dark label written on the film roll. The film will then be printed with the date and production batch code. There are generally two types of printers: standard (uses black ribbon) and TTO (uses white ribbon (thermal transfer overprint))

Bag Making

Once the film is finished printing, it is transferred to bag manufacturing to be molded. It is similar to the collar of human clothing. This bag molding makes it possible to produce a wide variety of bags or pouches. Bag making machines of different sizes can be used to make bags of different sizes. If bags of different sizes need to be packed, the training cubes must be replaced. Switching only takes a few minutes. In addition to bag making function, the bag making machine also has filling function. Thanks to it, bulk materials will be poured into bags. The bag obtained is made of stainless steel and is therefore food grade.

Filling And Sealing

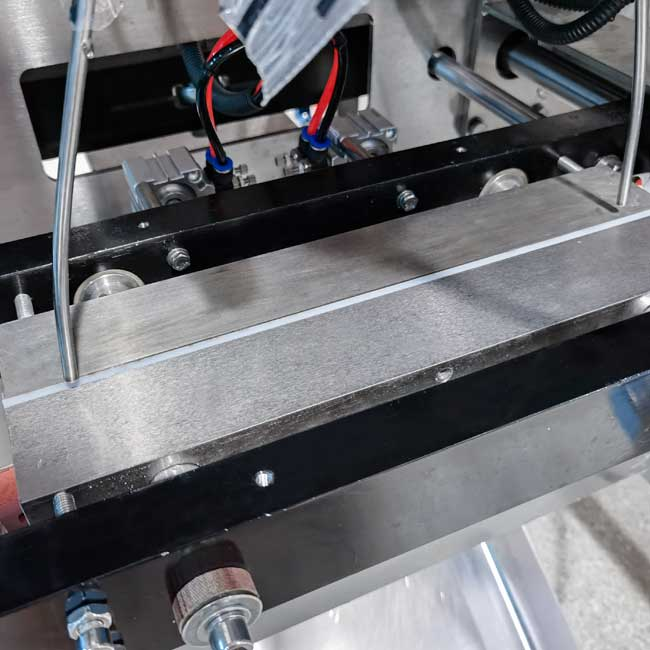

Soonk vertical packaging machine is equipped with two sets of sealing devices. The first is a vertical sealer, while the second is a horizontal sealer. It creates vertical patterns with two vertical sealing jaws. When you use a single vertical sealer and push the bag machine, a flat or mesh pattern is created. Different types of sealants can achieve different sealing patterns. Once the bag is sealed, the weighed bulk items are placed inside the bag.

The machine’s operation is managed via a control panel or interface, where parameters like bag length, speed, and seal temperatures are set. For products requiring printed information like expiration dates, a printing or date coding system is included. Once the bags are filled and sealed, they are carried away by a product discharge conveyor for further processing or packaging.

Additionally, Soonk vertical machine may include sensors and safety features for smooth operation and operator safety, detecting issues like film jams or abnormal temperatures. Optional components like an air or inert gas flushing system can be added for products needing protection from oxidation, extending shelf life. In cases where static electricity is a concern, a static eliminator is also incorporated.

Each vertical packing machine can be uniquely configured to meet the specific packaging requirements of different products, demonstrating the versatility and importance of these machines in the packaging industry.

Conclusion

In conclusion, Soonk vertical packing machines, or (VFFS) machines, are indispensable in the modern packaging industry. They offer a highly efficient and versatile solution for packaging a wide array of products, ranging from food items to industrial components. The essential components of these machines, including the hopper, weighing systems, film handling mechanisms, forming tubes, sealing bars, and control panels, work in unison to ensure the seamless transformation of raw materials into securely packaged goods.

The ability to customize and add optional features like printing systems, gas flushing, and static eliminators further enhances their functionality, making them adaptable to specific industry requirements. The integration of safety features and advanced sensors underscores a commitment to operational efficiency and workplace safety.